Hubbard Mechanical field involves designing, developing, and producing various mechanical systems and machines. Its impact is felt in every aspect of our daily lives.

To succeed in this role, candidates must have excellent CAD skills that allow them to create blueprints that fulfill client briefs. They also need to think critically and solve problems quickly and accurately.

Engineers consider the physical and operational parameters of machines, components, or products in a mechanical design process. They may design a new product or machine from the ground up or improve existing technology through several methods. These techniques may include incorporating new materials, employing advanced manufacturing processes, or re-engineering the components. Whatever the case, all mechanical designs must be thoroughly analyzed and vetted for safety and effectiveness.

Ideally, all design considerations should be considered from the beginning of the project. This will allow designers to create a system optimized for the desired operating conditions. For example, a device that works well in the snow could fail in the desert, so testing its performance under various conditions from the outset is important.

It is also critical for designers to define energy efficiency goals early in the project. These goals should be clearly defined and documented to guide decisions throughout the design process. In addition, it is helpful to involve all stakeholders from the outset to collaborate and develop ideas. This will help to identify any issues that might be impeded by production, such as cost or availability of raw materials.

Developing the right balance between form and function is a key part of a mechanical design project. Often, this requires compromises between the desires of the occupants of the building or machine and those of the architects or owners. For example, occupants are often concerned with comfort, while owners and architects want to maximize space. However, it is the designer’s job to find a healthy medium.

The most valuable skills that mechanical design engineers possess are critical thinking, analytical reasoning, and communication. They must be able to assess risks and make data-driven informed decisions. Proficiency in computer-aided design (CAD) software is also a must.

A CAD program will help designers create 3D models of machines, components, and parts and analyze their structural integrity and performance. It will also enable them to generate technical drawings and documentation. In addition, a CAD program will help reduce the amount of material required for fabrication. This will help lower costs, speed up time-to-market, and reduce environmental impact.

A mechanical testing engineer tests materials and structures to withstand various loads and stresses. These tests can be conducted either in-house or at an external laboratory. They can also be done on a scheduled or as-needed basis, depending on the situation and the client’s needs. Mechanical testing is a vital part of the design and manufacturing process. It can help manufacturers identify weaknesses and flaws in their products and make improvements before they hit the market. It can also help ensure users’ safety and that structures can withstand a wide range of environmental factors throughout their lifetimes.

Mechanical tests that can be performed on a material or product include tensile testing, compression testing, flexural testing, peel testing, shear testing, fatigue testing, creep testing, and impact testing. Most of these tests use a universal machine designed to perform various standardized mechanical test methods. These machines can be used to test raw materials and finished products and are often more accurate than manual methods.

Mechanical testing is crucial for the development of new materials and prototypes. It allows engineers to evaluate the performance of different materials under various conditions, which can help them optimize designs and find better solutions for their clients. They can also use the results of these tests to predict how their products will perform in real-world environments.

Another important use of mechanical testing is ensuring that a finished product meets all the necessary quality standards. Manufacturers can also use the results of these tests to develop better products and reduce production costs. This helps them maintain a good reputation and increase their sales. They can also avoid costly production mistakes by avoiding the use of low-quality materials.

Mechanical testing is a vital step in developing any material or structure. It can assess various components’ strength, durability, and reliability, including those in aircraft, cars, bridges, and buildings. In addition, it can help manufacturers determine the safety and quality of their products by subjecting them to simulated environmental stresses.

The production of a mechanical system or part involves converting raw materials or semi-finished goods into a finished product using man and machinery. Mechanical engineers perform this function by analyzing designs and overseeing the production process. They may also perform analytical and computational assessments of mechanical systems to ensure they meet functional requirements and safety standards. The design and construction of mechanical devices require an extensive knowledge of physics, mathematics, computer science, and project management.

Manufacturing of a mechanical system may be done manually or through machine tools, depending on the type and complexity of the product being manufactured. For example, a complex machine tool might cut or shape metal components such as engines, airplanes, and cars. The equipment’s instructions must be fed into the machine through programmed instruction or a computer-aided engineering (CAD) and computer-aided manufacturing (CAM) program.

Other types of mechanical manufacturing include machining, forming, welding, and casting. Mechanical engineers specializing in machining can work in the aerospace, automotive, and marine engineering industries. They often work with a team of engineers to complete complex projects that require multiple steps.

A mechanical engineer calculates the energy required to operate a mechanical device or system. This is known as energy efficiency. It is an essential measurement in the production of any mechanical device, as it determines how much energy is being utilized to produce a given level of work.

The mechanical engineer must also consider how a machine will perform under different conditions, such as temperature or weather. Mechanical engineers specializing in thermal and acoustic systems can work in air conditioning, heating, and ventilation. They also may work on elevators, escalators, and other moving structures within buildings.

The mechanical engineer must communicate effectively, both verbally and in writing. They must be able to explain technical information and concepts to non-engineers and translate and present data. They should be able to analyze problems and find solutions through creative thinking, as well as be able to work as part of a team.

Maintenance of mechanical systems is a complex and ongoing process. This involves identifying and repairing problems with machines, ensuring that they function correctly, and maximizing their efficiency and lifespan. These activities can be either reactive, such as a repair after a breakdown, or proactive, such as preventive maintenance.

Keeping tabs on machinery maintenance is essential for any business that relies on large amounts of equipment. This includes food and beverage companies that must ensure their production lines operate smoothly to meet strict health and safety standards. Larger buildings also have many mechanical equipment, from fans to boilers and pumps, which must be carefully tracked. These large and expensive machines are a critical part of the building’s infrastructure, and their downtime can affect staff productivity.

A mechanical maintenance system can track and manage all of these assets. It can help to optimize operations, reducing energy waste and lowering operational costs. It can also detect problems and make repairs before they become more serious, saving the company money. A mechanical maintenance system can perform various tasks, including adjusting and lubricating equipment, cleaning machines, and troubleshooting. It can also provide reports on equipment status, enabling managers to plan and budget maintenance activities.

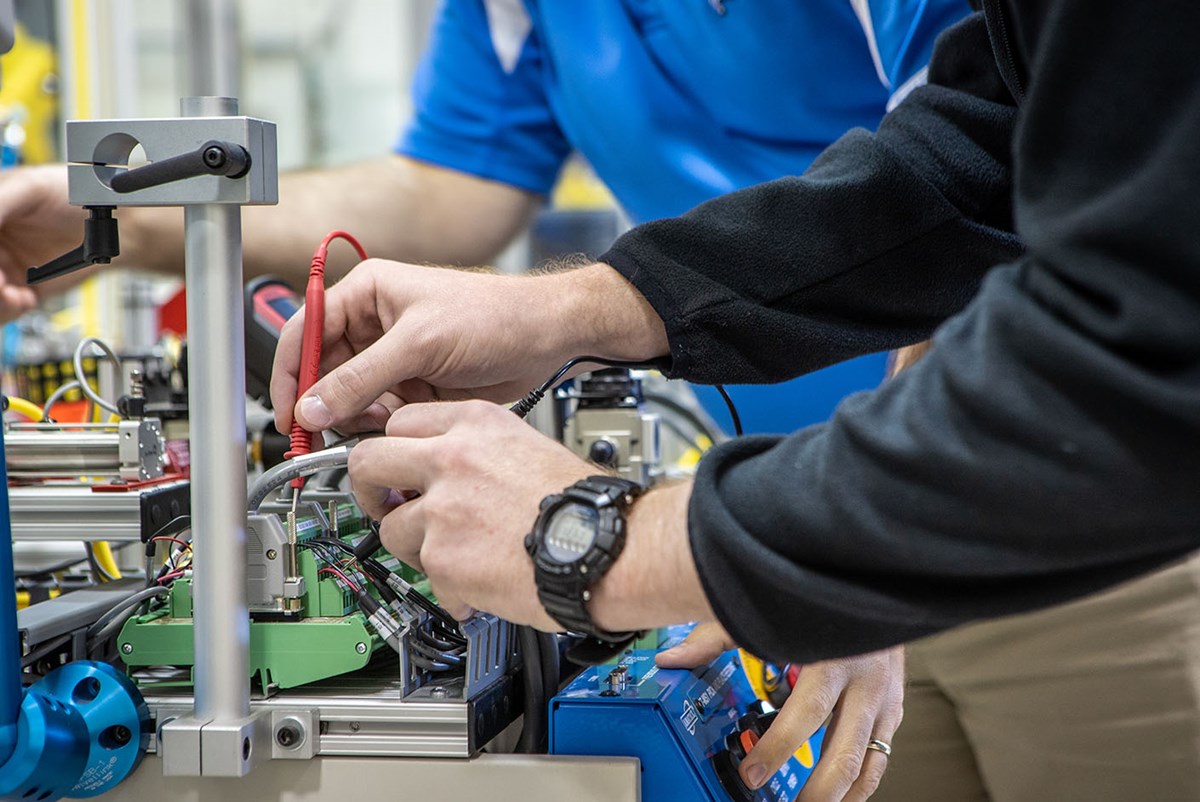

Mechanical maintenance technicians are responsible for the inspection, repair, and replacement of machines in a wide range of industries. These workers must have good manual dexterity and be able to work with their hands. They may have advanced technical training or certifications and often work on industrial equipment in power plants, factories, construction sites, and other commercial facilities.

Typical duties include inspecting, servicing, and repairing large production machinery. They are also responsible for repairing and adjusting heating, ventilation, air conditioning systems, laundry bridges, refrigeration units, electric and gas-powered motors, compressors, and pumps. They also clean, organize, inventory, and stock tools, parts, and supplies. An administrative superior usually gives them general supervision, but they have considerable independence in their daily work.

Preventive maintenance is a set of inspections and servicing activities conducted on a scheduled basis to minimize untimely failure of machine components or systems. Engineers, technicians, or mechanics trained according to fashionable methods laid down by the technical government perform preventive maintenance.